Manifold Heater

Manifold Heater Specification

- Phase

- Single/Three Phase

- Terminal Type

- Lead Wire / Screw Terminal

- Frequency

- 50/60 Hz

- Application Areas

- Hot Runner Mold, Plastic Injection Machines, Packaging Equipment

- Mounting Type

- Clamp/Flange

- Heating Element

- Nichrome (NiCr) Wire

- Features

- High Thermal Efficiency, Uniform Heat Distribution, Fast Heating, Durable

- Temperature

- up to 450C

- Usage

- Industrial Heating, Mold Heating, Die Heating

- Diameter

- 6 mm - 20 mm

- Voltage

- 230 V / 415 V

- Material Specified

- Stainless Steel

- Insulation Material

- Ceramic Fiber

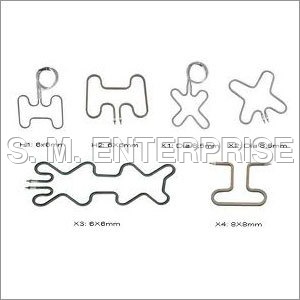

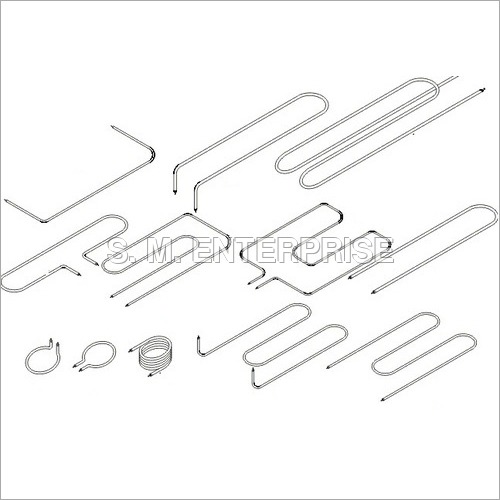

- Shape

- Tubular

- Power

- 500 W - 3000 W (Customizable)

- Lead Wire Length

- 1 meter (standard), customizable

- Connector Type

- Standard/Customized Connectors

- Ambient Operating Conditions

- Suitable for humid environments

- Maximum Operating Pressure

- 5 bar

- Surface Finish

- Polished

- Thermal Response Time

- Rapid

- Resistance Tolerance

- ±10%

- Control Method

- External Thermostat Compatible

- Sheath Material

- SS304/SS316

- Length

- Custom Lengths Available (per requirement)

- Ingress Protection

- IP55

About Manifold Heater

Established in year 1972, we are one of the promising manufacturers and suppliers of Manifold Heater. Purpose of this heater is to heat fuel mixture to help in vaporization when an engine is started at temperature below 150 degrees Fahrenheit. This is made offered in stainless steel. Manifold Heater has easy installation, robust design, durable construction, less power consumption, low maintenance, and durability. Our product operates at 220-volt electric power supply and has a large maximum operating temperature.

Features:

-

Tabular in shape

-

Power (Watts) used is 400-3000 W

-

Consistent heating capacity

Customizable Precision for Industrial Applications

Every Manifold Heater can be precisely tailored in length, power, voltage, and connector type to perfectly fit your unique requirements. The choice of stainless steel SS304/SS316 sheath and polished finish assures long-lasting durability even under demanding industrial environments.

Exceptional Thermal Performance and Efficiency

With rapid heat-up times, uniform heat distribution, and high thermal efficiency, our heaters ensure optimal temperature control for processes like mold heating and plastic injection. The ceramic fiber insulation further enhances performance and safety.

Reliable Operation in Challenging Environments

IP55 ingress protection and robust materials mean our Manifold Heaters are well-suited for humid and demanding ambient conditions. The design accommodates both clamp and flange mounting, catering to various industrial setups, while external thermostat compatibility enables precise temperature regulation.

FAQs of Manifold Heater:

Q: How can I specify the length and connector type for a Manifold Heater order?

A: You may request custom lengths and either standard or customized connector types when placing your order. Our engineering team will tailor the heater to your specifications to ensure a perfect fit for your application.Q: What benefits does the IP55 ingress protection offer in industrial environments?

A: IP55 protection allows the heater to operate reliably in humid or dusty settings, safeguarding the internal components against water and airborne particles, which reduces maintenance and extends service life.Q: When should a manifold heater be used instead of other heating solutions?

A: Manifold heaters are ideal for applications requiring uniform heating across complex surfaces, such as hot runner molds, packaging equipment, and die heating, where rapid thermal response and precise temperature control are critical.Q: Where are these manifold heaters commonly installed?

A: These heaters are most often installed in industrial machinery like plastic injection machines and hot runner molds, using either clamp or flange mounting depending on equipment requirements.Q: What is the process for installing a manifold heater with an external thermostat?

A: Installation involves mounting the heater using the provided clamp or flange, connecting the lead wire or screw terminal to the power supply, and linking the external thermostat for accurate temperature control throughout operation.Q: How does the ceramic fiber insulation benefit heater performance?

A: Ceramic fiber insulation enhances energy efficiency by minimizing heat loss and enabling more uniform heat distribution, which results in stable process temperatures and improved safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tubular Heater Category

Strip Heaters

Price 500 INR

Minimum Order Quantity : 10 Pieces

Material Specified : Other

Power : Up to 1000 W

Shape : AS PER CUSTOMIZED

Insulation Material : Ceramic or Mica

Finned Tubular Heater

Price 450.0 INR / Piece

Minimum Order Quantity : 6 Pieces

Material Specified : Other, Stainless Steel

Power : 1000 W to 5000 W

Shape : U Shape

Insulation Material : MGO (Magnesium Oxide)

Tubular Heating Elements

Price 449.0 INR / Piece

Minimum Order Quantity : 3 Pieces

Material Specified : Other

Power : 100W to 5000W Watt (w)

Shape : Tubular

Insulation Material : MgO (Magnesium Oxide)

Customized Stainless Steel Tubular Heater

Material Specified : Stainless Steel, Other

Power : 1500W

Shape : Tubular

Insulation Material : Ceramic

Send Inquiry

Send Inquiry Send SMS

Send SMS