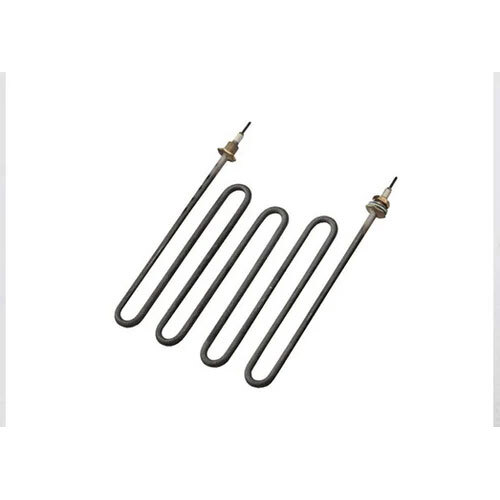

Hopper Heaters

Hopper Heaters Specification

- Usage

- Industrial

- Size

- As per customized

- Insulation Material

- Stainless Steel

- Shape

- U Shape

- Power

- 110 Volt (v)

- Color

- Silvar

Hopper Heaters Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Hopper Heaters

Hopper heaters are specialized heating devices designed to maintain or raise the temperature of materials stored in hoppers, bins, or silos. They are commonly used in various industries, including plastics, food processing, pharmaceuticals, and agriculture. These heaters ensure that materials like powders, granules, or liquids remain at optimal temperatures to facilitate processing, prevent clumping, or reduce viscosity.

Key Features:

- Heating Methods: Often utilize electric resistance heating, convection, or infrared heating techniques to provide efficient heat transfer.

- Temperature Control: Equipped with thermostats or digital controllers for precise temperature management.

- Material Compatibility: Designed to accommodate a range of materials, including plastics, chemicals, and food products, ensuring safe and effective heating.

- Durability: Built with robust materials to withstand harsh industrial environments and frequent use.

- Safety Features: Include thermal cutoffs, over-temperature protection, and insulated designs to prevent heat loss and ensure safe operation.

FAQs

1. How do hopper heaters work?Hopper heaters function by applying heat to the hoppers walls or directly to the material inside, using electric elements or other heating methods to maintain the desired temperature.

2. What materials can be heated with hopper heaters?Hopper heaters can be used for a variety of materials, including powders, granules, and liquids, commonly found in industries like plastics, food processing, and chemicals.

3. Why is temperature control important in hoppers?Maintaining the right temperature helps prevent material clumping, ensures consistent flow, reduces viscosity in liquids, and improves processing efficiency.

4. Are hopper heaters energy-efficient?Many modern hopper heaters are designed with energy efficiency in mind, utilizing insulation and advanced controls to minimize energy consumption while maintaining desired temperatures.

5. What are the common applications of hopper heaters?Common applications include keeping plastic pellets warm before extrusion, maintaining flowability in powdered materials, and ensuring proper viscosity in liquid food products.

6. How do I choose the right hopper heater for my application?Selection depends on factors such as the material type, desired temperature range, hopper size, and heating method. Consulting with a manufacturer or supplier can help identify the best option.

7. Are there safety concerns with using hopper heaters?Yes, safety is crucial. Ensure the heater has built-in safety features, is properly installed, and is monitored for temperature and material integrity to avoid overheating or material degradation.

8. How do I maintain my hopper heater?Regular maintenance includes inspecting heating elements for wear, checking electrical connections, cleaning any accumulated material, and testing safety features.

9. Can hopper heaters be integrated into automated systems?Yes, many hopper heaters can be integrated with automation systems for improved monitoring and control, allowing for precise temperature regulation.

10. What is the average lifespan of a hopper heater?With proper care and usage, hopper heaters can last anywhere from 5 to 15 years, depending on the specific model and operating conditions

Versatile Industrial Application

These Hopper Heaters are designed for demanding environments, making them suitable for industries such as plastics, food processing, and chemicals. Their U shape facilitates optimal heat distribution, while the ability to customize size ensures compatibility with different hopper designs, enhancing operational flexibility and efficiency.

Superior Insulation with Stainless Steel

Featuring stainless steel insulation, these heaters offer excellent durability and temperature control. This material helps minimize energy loss and withstands harsh working conditions, improving the longevity of both the heater and the host equipment. Stainless steel is also resistant to corrosion, making the heater a reliable choice for extended use.

FAQs of Hopper Heaters:

Q: How are Hopper Heaters installed in industrial setups?

A: Hopper Heaters are custom-fitted to the specific dimensions of your hopper. Their U shape allows for easy attachment, usually by clamping or securing them against the hopper wall. Professional installation ensures optimal heat transfer and safety in industrial applications.Q: What industries commonly use Hopper Heaters?

A: Industries like plastics processing, food manufacturing, and chemical production often rely on Hopper Heaters to maintain consistent material temperatures in bins and silos. Their robust stainless steel construction makes them suitable for high-demand environments.Q: When should Hopper Heaters be utilized in operations?

A: Hopper Heaters are recommended when temperature-sensitive materials must be kept at a consistent temperature to prevent clogging, moisture absorption, or crystallization. They are often used during storage, pre-processing, or transport phases.Q: Where are Hopper Heaters supplied and exported from?

A: These heaters are designed, manufactured, and supplied from India by a reputable exporter. They are distributed both domestically and internationally to meet industrial requirements worldwide.Q: What is the process for customizing Hopper Heaters?

A: You can request Hopper Heaters in custom sizes suitable for your specific hopper dimensions. The manufacturer works with you to determine requirements, then fabricates the heater with tailored specifications, ensuring an exact fit and optimal functionality.Q: How does the stainless steel insulation benefit operational efficiency?

A: Stainless steel insulation enhances energy efficiency by reducing heat loss, ensuring the hopper remains at the required temperature, and providing durability against corrosion and wear. This leads to a longer heater lifespan and stable performance.Q: What is the optimal power setting for these Hopper Heaters?

A: Each Hopper Heater is designed to operate at 110 volts, offering reliable performance while remaining compatible with standard industrial electrical systems. This adaptability makes installation straightforward across various facilities.

Price 2320 INR/ Piece

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tubular Heater Category

Tube Heaters

Price 2350.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Insulation Material : Stainless Steel

Shape : U Shape

Power : 220 Volt (v)

Various Shape Stainless Steel Tubular Heater

Price 251.0 INR / Piece

Minimum Order Quantity : 6 Pieces

Insulation Material : Magnesium Oxide

Shape : Various

Power : 1000 Statampere (sA)

Warranty : 1 Year

Heating Elements

Insulation Material : Ceramic

Shape : Coiled

Power : 3000 Watt (w)

Warranty : 1 Year

Send Inquiry

Send Inquiry Send SMS

Send SMS