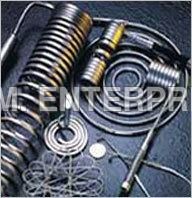

Circulation Heaters

Circulation Heaters Specification

- Usage

- Industrial

- Size

- Standard

- Insulation Material

- MS

- Product Type

- Circulation Heaters

- Color

- Silver

- Warranty

- 1 Year

Circulation Heaters Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 7 Days

About Circulation Heaters

Circulation heaters combine with a tank, insulation, terminal enclosure, mounting brackets, inlet, and outlet connections to form a complete assembly. Circulation heaters, therefore, provide a ready-made means to install electric heating with a minimal amount of time and labor.

Circulation heaters are designed to force circulated liquids (air and gases may also be appropriate depending upon the application) over a heating element. Circulation heaters are ideal for either in-line or side-arm operations. By using heating elements, these circulation heaters deliver fast response and even heat distribution.

Circulation heaters maintain the high performance capabilities for which all heaters are known. Circulation heaters are rated up to one megawatt , generating watt densities up to 120 W/in2 and sheath temperatures of up to 1600F (depending upon sheath material).The tanks are insulated with one inch of thermal insulation rated to 750F to reduce heat loss. A heavy gauge steel jacket protects the entire assembly. A wide range of sheath materials, wattages, vessel sizes and materials, pressure ratings, terminal enclosures and controls are available to the circulation heaters to meet virtually all your circulation heater assembly needs.

Applications:-

Industrial water rinse tanks

Hydraulic oil, crude, asphalt

Lubricating oils at API specified watt densities

Heat Transfer Oil

Paraffin

Caustic cleaners

Nitrogen, hydrogen and other air/gas systems

Superheating steam

Water:-

Deionized

Demineralized

Clean

Potable

Process

Robust Industrial Performance

Designed for rigorous industrial environments, our Circulation Heaters are built with premium MS insulation and offer dependable performance for heating liquids and gases. Their standard size and silver finish ensure they integrate seamlessly into existing systems.

Reliable Indian Manufacturing

As a leading manufacturer, supplier, and exporter from India, we emphasize quality control and efficient delivery. Our Circulation Heaters are crafted with precision to meet both domestic and international requirements.

FAQs of Circulation Heaters:

Q: How can Circulation Heaters be used in industrial environments?

A: Circulation Heaters are commonly used in industrial applications to heat liquids or gases by circulating them through a heated chamber. They ensure consistent and precise temperature control in processes like chemical treatment, oil heating, and water processing.Q: What insulation material is employed in these heaters, and why?

A: Our heaters utilize mild steel (MS) insulation. MS is chosen for its durability and cost-effectiveness, providing robust protection and minimizing heat loss during operation.Q: When should I consider replacing or servicing my Circulation Heater?

A: Regular maintenance allows for optimal efficiency. We recommend inspecting your heater annually and making use of our 1-year warranty for repairs or replacements if performance issues arise.Q: Where are your Circulation Heaters manufactured and shipped from?

A: All our Circulation Heaters are manufactured in India. We export nationally and internationally, ensuring timely supply to a diverse clientele.Q: What is the installation process for these standard-sized heaters?

A: Installation involves connecting the heater inline with your process system. Due to the standard sizing, our Circulation Heaters fit seamlessly into most industrial setups, reducing downtime and simplifying integration.Q: How does the 1-year warranty benefit customers?

A: The 1-year warranty ensures peace of mind. Any manufacturing or operational defects within the warranty period will be addressed promptly, minimizing disruptions to your industrial process.Q: What are the primary benefits of using your Circulation Heaters in industrial applications?

A: The main benefits include robust durability due to MS construction, optimal thermal efficiency through quality insulation, ease of installation with standard sizing, and reliable after-sales support from an experienced Indian manufacturer.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 7 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Heaters Category

Oil Out Flow Heaters

Insulation Material : Ceramic Fiber

Shape : Cylindrical

Material Specified : Other, Mild Steel / Stainless Steel

Power : 0.5 KW to 12 KW

Drum Heaters

Insulation Material : Fiberglass / Mineral Wool

Shape : Round / Cylindrical Band

Material Specified : Other, Silicon Rubber / Stainless Steel / Mild Steel

Power : 500W to 2000W (Customizable)

Immersion Heaters

Minimum Order Quantity : 10 Pieces

Insulation Material : Aluminum

Shape : Round

Material Specified : Other, Immersion Heaters

Warranty : 1 Year

Send Inquiry

Send Inquiry Send SMS

Send SMS