Industrial Electric Heaters

Industrial Electric Heaters Specification

- Usage

- Heaters

- Color

- Silvar

- Size

- Customized

- Insulation Material

- Titanium

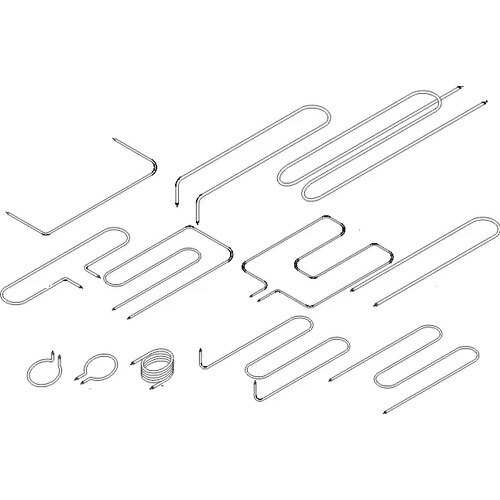

- Shape

- VARIOUS SHAPE

- Power

- 220 Volt (v)

Industrial Electric Heaters Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Industrial Electric Heaters

Industrial electric heaters are devices used to generate heat for a variety of industrial applications. These heaters convert electrical energy into thermal energy and are designed to meet the demands of heavy-duty operations in sectors such as manufacturing, chemical processing, food and beverage, and more. They can be used for heating liquids, gases, or solids and come in various forms, including resistance heaters, infrared heaters, and immersion heaters.

Key Features:

- Variety of Types: Includes resistance heaters, infrared heaters, cartridge heaters, and immersion heaters, each suited for specific applications.

- Power Ratings: Available in a wide range of power outputs to accommodate different heating requirements, from small-scale operations to large industrial setups.

- Durability: Constructed from robust materials such as stainless steel or high-temperature alloys to withstand harsh environments.

- Control Options: Often come with advanced controls, including programmable thermostats and digital displays, for precise temperature regulation.

- Safety Features: Designed with multiple safety mechanisms, including thermal cutoffs, overload protection, and fail-safes to prevent overheating.

FAQs

1. How do industrial electric heaters work?Industrial electric heaters function by converting electrical energy into heat through various mechanisms, such as resistance heating, where current passes through a resistive material, generating heat.

2. What are the common applications of industrial electric heaters?These heaters are used in numerous applications, including process heating, space heating, drying processes, water heating, and as part of industrial machinery.

3. How do I select the right type of industrial electric heater?The selection depends on factors such as the type of material to be heated, the desired temperature, the heating method, and the specific application requirements.

4. Are there energy efficiency considerations?Yes, energy efficiency can vary widely among heater types. Look for models with good thermal insulation, precise controls, and features that minimize heat loss to ensure optimal efficiency.

5. What are the safety considerations when using industrial electric heaters?Safety is critical. Ensure proper installation by qualified personnel, conduct regular maintenance, and check for compliance with local safety standards and regulations.

6. Can industrial electric heaters operate in hazardous environments?Yes, but its essential to choose heaters designed for hazardous locations (explosion-proof) and to follow stringent safety protocols to mitigate risks.

7. How do I maintain my industrial electric heater?Maintenance typically involves regular inspections for wear, cleaning heating elements, checking electrical connections, and ensuring safety features function correctly.

8. What is the average lifespan of an industrial electric heater?With proper care and usage, many industrial electric heaters can last 10 to 20 years, although this can vary based on the specific type and operating conditions.

9. Can these heaters be used with automation systems?Yes, many industrial electric heaters can be integrated into automated systems for monitoring and control, allowing for precise temperature management and improved efficiency.

10. What are the installation requirements for industrial electric heaters?Installation requirements depend on the heater type and application. It typically involves electrical connections, mounting provisions, and adherence to local building codes and safety standards

Price 2000 INR/ Piece

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Heater Category

Corrugation Machine Heater

Insulation Material : stainless steel

Shape : VARIOUS SHAPE

Material Specified : Other, Corrugation Machine Heater

Power : 220 Volt (v)

ESP Hopper Heater

Insulation Material : Ceramic

Shape : Rectangular

Material Specified : Other, Stainless Steel

Power : 500W

Warranty : 1 year

Washing Machine Water Heater Element

Insulation Material : Ceramic

Shape : Ushape

Material Specified : Other, Stainless Steel

Power : 2000W

Warranty : 1 year

Aluminium Casted Heaters

Insulation Material : Ceramic

Shape : Varied (Round Rectangular Curved)

Material Specified : Aluminium, Other

Power : Customizable

Warranty : 1 Year

Send Inquiry

Send Inquiry Send SMS

Send SMS