Corrugation Machine Heater

Corrugation Machine Heater Specification

- Usage

- PAPER PACKAGING

- Material Specified

- Corrugation Machine Heater

- Insulation Material

- stainless steel

- Size

- AS PER CUSTOMIZED

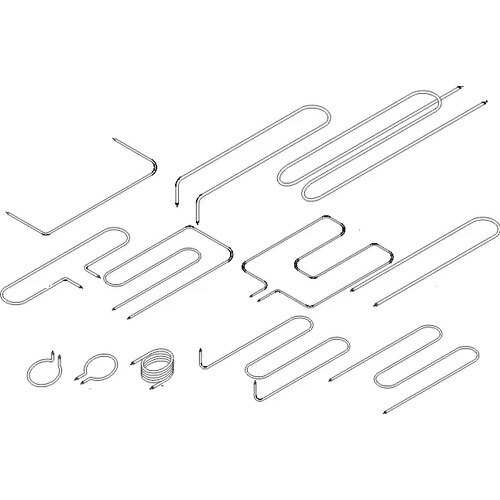

- Shape

- VARIOUS SHAPE

- Power

- 220 Volt (v)

- Color

- Brown

Corrugation Machine Heater Trade Information

- Minimum Order Quantity

- 5 Units

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Corrugation Machine Heater

Corrugation machine heaters are specialized heating devices designed for use in the corrugation process of paper and cardboard manufacturing. These heaters provide consistent and controlled heat to the corrugating rollers and other components, ensuring optimal adhesion and strength of the finished product. By maintaining the correct temperature, they help improve the efficiency and quality of the corrugation process.

Key Features:

- Temperature Control: Equipped with advanced temperature regulation systems to maintain optimal heating for various materials and processes.

- Durable Construction: Made from high-quality materials to withstand the rigors of industrial use and provide long-lasting performance.

- Energy Efficiency: Designed to minimize energy consumption while providing consistent heat, reducing operational costs.

- Easy Installation: Typically designed for straightforward integration into existing corrugation machines.

FAQs

1. What are the primary applications of corrugation machine heaters?

- They are primarily used in the paper and cardboard manufacturing industry, specifically for the corrugation process, ensuring proper adhesion and strength of corrugated materials.

2. How do corrugation machine heaters work?

- These heaters typically use electric heating elements that generate heat, which is then transferred to the corrugating rollers and other components to maintain the desired temperature.

3. What are the advantages of using dedicated corrugation machine heaters?

- They provide precise temperature control, enhance production efficiency, improve product quality, and are built to withstand the demands of continuous operation.

4. Can these heaters be used with different types of corrugation machines?

- Yes, most corrugation machine heaters are designed to be compatible with a variety of machine models, but its important to verify specifications to ensure proper fit and function.

5. What materials are commonly used in the construction of these heaters?

- Corrugation machine heaters are typically made from durable materials such as stainless steel or aluminum, designed for high-temperature applications.

6. How do I choose the right corrugation machine heater for my needs?

- Consider factors such as the specific machine model, required heating capacity, temperature range, and any other process requirements. Consulting the manufacturers specifications is crucial.

7. What maintenance is required for corrugation machine heaters?

- Regular inspections for wear and tear, cleaning of dust and debris, and checking electrical connections are essential for maintaining optimal performance.

8. Are corrugation machine heaters energy-efficient?

- Yes, these heaters are designed to optimize energy use while delivering the necessary heat for effective corrugation, helping to reduce overall energy costs.

Custom-Built for Corrugation Needs

Our Corrugation Machine Heater stands out with its capacity for customization, being available in various shapes and sizes. Whether youre upgrading current equipment or installing a new system, this heater can be tailored to your precise specifications, enhancing the efficiency of your paper packaging production line.

High-Performance Materials and Design

Constructed using stainless steel as the main insulation material, these heaters are built to withstand the high demands of the corrugation process. Stainless steel enhances durability, resists corrosion, and ensures efficient thermal conductivity for continuous operation. The brown finish easily blends with most industrial machine setups.

FAQs of Corrugation Machine Heater:

Q: How does the Corrugation Machine Heater improve the paper packaging process?

A: The heater delivers consistent and controlled heat, which is critical during corrugation as it conditions the paper and allows for optimal bonding and smooth operation. This ensures higher quality end products and reduces downtime caused by temperature fluctuations.Q: What customization options are available for the Corrugation Machine Heater?

A: You can specify the shape and size of the heater to match your corrugation machines requirements. Our manufacturing process accommodates a variety of production lines, ensuring each heater integrates seamlessly with your existing setup.Q: When is it recommended to replace or upgrade a corrugation machine heater?

A: Its advisable to replace or upgrade heaters when you notice inconsistent heat distribution, increased energy usage, or frequent breakdowns. Periodic maintenance and inspection are important to ensure continuous, efficient operation.Q: Where are these heaters manufactured and supplied from?

A: These heaters are manufactured, exported, and supplied from India. As an experienced manufacturer and exporter, we cater to both domestic and international clients requiring reliable corrugation machine heaters.Q: What is the process for installing the customized heater onto existing machinery?

A: Installation involves aligning the customized heater with your machines specifications, ensuring secure electrical connections, and verifying insulation. Our technical support is available to guide you through installation for seamless integration.Q: How do users benefit from the stainless steel insulation material?

A: Stainless steel provides excellent resistance to corrosion and high temperatures, promoting prolonged heater life and efficient thermal performance. This helps in reducing maintenance needs and operational costs over time.Q: What is the usual operating voltage for the Corrugation Machine Heater?

A: The heater operates on a standard 220 Volt supply, making it compatible with most industrial power sources. This allows for easy installation and use in various paper packaging facilities.

Price 2300.00 INR/ Unit

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 1000 Units Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Heater Category

Industrial Electric Heaters

Power : 220 Volt (v)

Shape : VARIOUS SHAPE

Insulation Material : Titanium

Water Kettle Heating Elements

Power : 1500W

Shape : Tubular

Insulation Material : Ceramic

Material Specified : Stainless Steel, Other

Warranty : 1 Year

ESP Hopper Heater

Power : 500W

Shape : Rectangular

Insulation Material : Ceramic

Material Specified : Other, Stainless Steel

Warranty : 1 year

Washing Machine Water Heater Element

Power : 2000W

Shape : Ushape

Insulation Material : Ceramic

Material Specified : Other, Stainless Steel

Warranty : 1 year

Send Inquiry

Send Inquiry Send SMS

Send SMS